Why Helical Piles are Gaining Popularity in Florida’s Foundation Repair

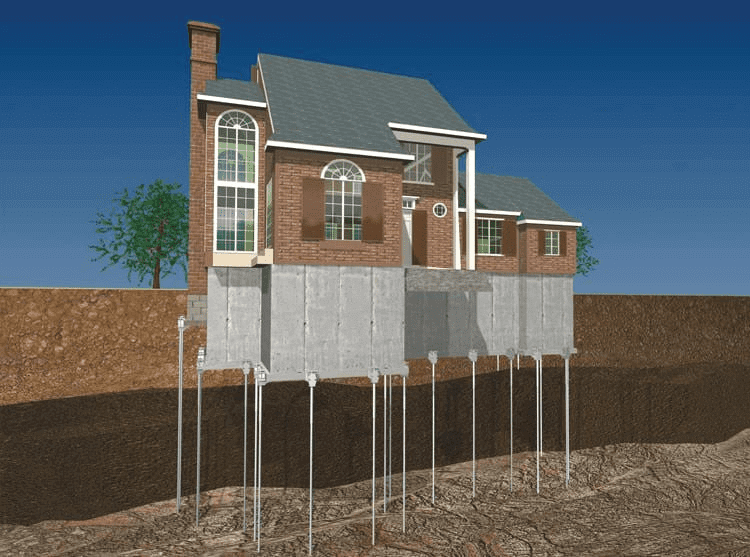

Foundation retrofitting involves strengthening and stabilizing existing foundations to prevent damage caused by earthquakes, erosion, or other factors. Helical piles – steel shafts with screwed-in plates at their ends – are one form of foundation retrofitting; this article discusses their advantages and drawbacks so you can decide if using steel helical piers is an option for your foundation project.

What Is A Helical Foundation Piles?

Helical pilings provide the foundations necessary for light and heavy structures, supporting loads from as little as 1kN (225lb) up to 5.125 million lb! They’re suitable for everything from small landings to 32-story towers – including landing strips! Sometimes known by its other name, “screw piles.”

A helical pile shaft consists of one or more bearing blades attached to its shaft, with their diameter, length, thickness, and number depending on a variety of factors such as thickness, diameter, number of pilings used as well as their pitch (plane angle or slope) regardless of dimensions for reliable helical pile installation methods that adhere to engineering regulations and specifications.

Why Helical Pier Foundation Are Commonly Used in Florida Homes?

Consider installing a helical pile foundation system when building a new home, home addition, or swimming pool. Over time, soil conditions around these properties may change; installing helical piles as part of their foundation system could increase their lifespan while providing support.

Why Does Soil Change Excessively in Florida?

Soil changes are the primary culprit behind foundation settlement, leading to cracked floors, uneven walls, and sinking foundations. Soil movement results from excessive moisture changes caused by droughts followed by saturation due to tropical rainfall or weather events like rainstorms in our tropical environment. When your gutter downspouts fail to discharge water correctly, this may contribute significantly. When combined together, this movement shifts and settles your foundation, creating cracked floors, uneven walls, or sinking foundations as a result of shifting.

The Helical Pier Installation Process

Screw piles or helical anchors may also be known as helical piles. Helical/Screw pilings are deep foundation piles used with concrete footings; their use requires hydraulic power head equipment until reaching their bearing capacity for your structure.

Potential Advantages of Helical-Piles include –

- Potential cost benefits as well as potential structural advantages.

- Installation is rapid and cost-effective

- Instant and Direct Load Capabilities on-site

- Eliminating noise or vibration concerns during construction.

- Installation at remote or limited-access sites

- Engineering to accommodate load capacities or any site restrictions

Benefits of Helical Piles Installation and Repair

Helical piles have quickly gained popularity because they provide many advantages over time. From solid foundation to environmental benefits and much more, Helical piling is increasingly utilized due to its many advantages.

- Installation of piles typically takes approximately 30 seconds per lineal foot of pile on most projects and does not require heating or hoarding in winter.

- They can be driven directly into the soil, resulting in no tailings or spoils being generated from their placement.

- Easy Remediation at Project Site: Helical piles can easily be taken apart and reused or recycled after they have served their purpose on-site, without disturbing neighbors or wildlife.

- Their low noise and vibration installations will have little or no adverse impact.

- Installing smaller equipment that’s more agile can reduce mobilization costs while making difficult project sites more accessible.

- Helical piles can be extended quickly at no additional expense.

- Ability to move through soil layers that are sloughing, sludging, and saturated without issue.

- Best resistance against frost-heave.

- Also, effective compression and tension solutions.

- It can be installed either end-bearing pile style or designed as a floating foundation system

- Anode systems can extend their lifetime by hundreds of years, and piles can easily be galvanized or thickened for additional longevity; also, they’re easily customizable in-field for unexpected conditions (ie, the helical diameter can decrease if soil density differs than expected).

- Helical piles can easily be installed under existing structures with limited access using various installation equipment.

- Helical piles are easy to transport and lightweight; additionally, their caps and transitions can be tailored specifically for any structural element or beam design.

- Winter building requires installing through frost for predictable performance.

- Utilizing torque of installation versus capacity ratios allows a pile to meet an obstacle like rocks without leaving it abandoned and falling over.

- Value engineering piles can be designed with multiple design modifications in order to increase effectiveness and efficiency, such as installation on the batter for high lateral forces or to combine groupings of piles in tight spaces.

What are the challenges of helical piles?

Traditionally speaking, there have also been challenges associated with these products, such as helical piles, that must be addressed.

Helical piles present numerous obstacles. For instance, their installation requires precise torque measurements and quality control measures in order to guarantee proper installation and performance. Furthermore, these structures may not be appropriate in environments such as areas with high water levels, corrosion issues, or large boulders and obstructions, not compatible with certain foundations or building codes and regulations, or protrusion from the ground requiring visible brackets and caps – among many other issues they pose challenges that need attention in order to remain effective solutions.

How can you identify whether or not helical pilings are suitable for my damaged foundation?

Decisions on retrofitting foundations with helical piles depend on many considerations, including site conditions, foundation type/condition, structural needs, budget considerations, and design preferences. Consult a construction engineer for help making an informed choice; they will evaluate your project to offer tailored advice regarding suitable retrofitting techniques, including helical piles. Finally, compare their pros/cons with respect to retrofitting techniques to gauge their suitability and feasibility for your particular project.

Where can I locate a reliable helical pile contractor?

Select a helical piles contractor with experience and an excellent track record who will deliver quality work and service, such as repairing helical pile foundations in your region. Check credentials, licenses, and certifications; request written contracts, warranties, and estimates from contractors; review their portfolio, testimonials, and references before initiating your project; communicate regularly with them to track their progress –

Affordable Foundation Repair: The Leading Helical Pile Contractor in Florida

Affordable Foundation Repair is one of the premier foundation companies for helical pier repair services. At Affordable Foundation Repair, our expert inspectors carefully survey every building they visit before conducting a comprehensive examination to assess its condition and make recommendations about how efficiently repairs should be conducted.

Affordable Foundation Repair is an established, fully licensed foundation repair company. We take great pride in being able to offer solutions for the foundation issues faced by businesses, homeowners, or builders! Whether helical piles need replacing, concrete wall repairs need to be done, or foundation issues need fixing… we have you covered – contact Affordable Foundation Repair now and receive up to $750 off on repairs!

0 comments

Write a comment